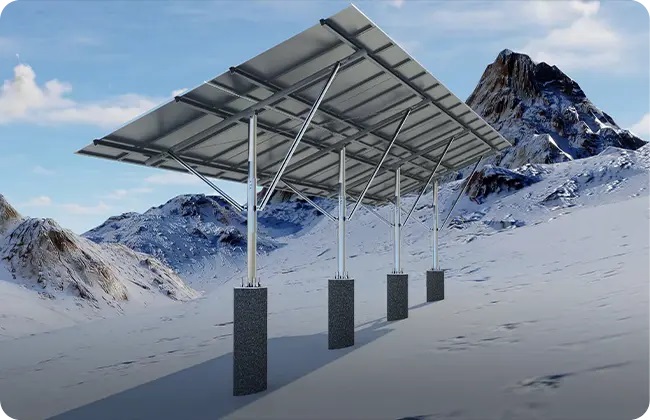

Solar PV modules can be installed either on the ground or on rooftops. This section mainly addresses the design requirements for foundations of ground-mount solar structures. In all cases, the supporting structures for PV modules must be firmly anchored to their foundations. The PV mounting foundation can be regarded as a critical structural component that transfers all functional loads borne by the supporting members of the PV modules to the ground.

Although the design and construction of PV mounting foundations account for a relatively small proportion of the total cost of a PV power plant, the large number of foundations involved means that their safety and economic performance have a significant impact on the stable operation of the plant. The design of PV mounting foundations must fully consider project topography, geological conditions, the form of the superstructure, construction load requirements, and construction methods. In addition, optimization and allocation should be carried out in accordance with the project schedule and local experience. The main design requirements include the following aspects.

The foundation design of PV mounting systems shall include verification of vertical bearing capacity (compression and uplift resistance), as well as verification of horizontal bearing capacity and overall stability for pile foundations. This ensures that the mounting structures can safely and reliably support PV modules under various weather conditions.

During design, factors such as the size, weight, and arrangement of PV modules shall be considered to ensure the stability of the mounting system. In addition, natural environmental actions such as wind loads, snow loads, and seismic effects must be taken into account.

Common pile foundation types include cast-in-place concrete piles, precast concrete piles, and steel pile caps, which are currently the most widely used supporting foundation forms in China. When pile foundations are adopted for PV mounting systems, pile caps are generally not used. Instead, the support columns are connected to the pile heads by means of insertion, welding, embedded anchor bolts, flange plates, or by adopting an integrated pile–column structure.

Cast-in-place piles are generally constructed using mechanized drilling, featuring simple construction procedures and the ability to adjust the elevation of the pile top according to terrain variations. However, cast-in-place piles are not suitable for weak soils, loose sandy soils, fractured rock, or sites with large groundwater level variations. In addition, on-site concrete casting is required, which makes curing and maintenance more difficult during winter construction.

Precast piles typically consist of prestressed concrete pipe piles with a diameter of approximately 300 mm or precast reinforced concrete square piles with cross-sectional dimensions of about 200 × 200 mm, which are driven into the ground. Steel plates or anchor bolts are reserved at the pile top for connection with the front and rear columns of the superstructure. Their load-bearing performance is similar to that of cast-in-place piles, with slightly higher costs, but they offer better adaptability to climatic conditions and shorter construction periods.

Prior to construction, detailed site investigations and confirmation of the design scheme shall be carried out, and safety shall be strictly observed during construction. The main construction process includes: setting out and excavating foundation pits on a leveled site, placing embedded components, installing formwork and positioning, pouring concrete, and installing the array mounting structures after 48 hours of curing.

The strength grade of concrete masonry blocks used in construction shall not be lower than MU10, the mortar strength grade shall not be lower than M5, and the concrete strength grade shall not be lower than C20. According to relevant technical specifications, PV mounting concrete foundations shall meet the following requirements: a concrete mix ratio of 1:2:4 (cement:sand:aggregate:water), using No. 42 cement or finer; aggregate particle size not exceeding 20 mm. The recommended foundation dimensions are 500 mm × 500 mm × 400 mm (length × width × height). For loose soil conditions, the foundation depth should be increased accordingly.

The foundation surface shall be level and smooth, and all foundations for the four support legs of a mounting structure shall be at the same elevation. Embedded anchor bolts shall be correctly positioned at the center of the foundation and kept vertical without inclination. The anchor bolts shall protrude 50 mm above the concrete surface, and any concrete on the exposed threads shall be cleaned. Attention shall also be paid to the orientation and spacing between the two foundations of each mounting structure.

During design, factors such as soil bearing capacity, topography, and geomorphology shall be considered to ensure both structural stability and environmental friendliness. With respect to bearing capacity requirements, PV array structural units within the same block should not be installed on significantly different foundation soils. Where soft cohesive soils, liquefiable soils, newly filled soils, or severely non-uniform soil layers are present, measures should be taken to enhance the integrity and stiffness of the foundation.

For example, in the presence of liquefiable soil layers, deep foundations may be adopted, with the foundation embedded into stable soil layers below the liquefaction depth by no less than 500 mm. Alternatively, soil improvement methods such as vibro-compaction, vibratory densification, or dynamic compaction may be used to reinforce the soil to below the lower boundary of the liquefaction depth. After treatment, the measured standard penetration test (SPT) blow counts of the soil layers shall exceed the corresponding critical values.